Two years ago I built my first guitar. Actually I rebuilt it. It was a guitar that my son had purchased from an amateur guitar builder. It was just an old guitar that had been painted to look like a Union Jack. I was interested in doing a project so I convinced my son to let me rebuild it. I stripped it all the way to the wood. Refinished it in white and replace all the hardware except for the pickups and tuners.

The big takeaway from that project: wiring is easy; refinishing is not.

This time my son proposed that we do a build together. He met a kid at Rock Camp that was interested in selling a Jackson Bass Guitar. The kid had stripped it down for parts. He was looking to sell the body and neck. It was in good shape except for some small chips and scratches.

The finish was in really good shape so I wanted to maintain it (remembering the lessons learned from the first build) . I also liked the color which I think is Ruby Red. I wasn’t sure how to fix the chips and maintain the finish so we took the body to the local Rockler store to get some advice.

I went and talked to the associate that I had spoken with during the first build. He’s an excellent resource – having worked on guitars before.

Unfortunately his advice was it down to the wood. Not what I wanted to hear.

The Rockler associate then suggested that I take it to the local luthier. Why hadn’t I thought of that?

(IMO, it’s a good idea to get to know you local luthier, especially if you’re just getting involved with guitars)

The luthier recommended using a touch-up paint on the chipped areas and then filling them in with Cyanoacrylate (CA). It can be applied in thin layers and then buffed to a shine.

Since one of the chipped areas was deeper than the others, I decided to fill it in a little with CA prior to painting it.

After a couple of layers, we primed the area with some primer that was left over from a previous project.

It’s common for guitar manufacturers to use automotive paint on their guitars. It shoots easy and is flexible. So my son and I grabbed the body and started visiting the local auto-parts stores in search for a touch-up paint that would match.

No luck.

The last store that we checked had a paint department that could do color matching. So I had the them run the process on the guitar and blend the paint for me. $12 got me a 2oz bottle of paint that was really close to the actual color. It turns out that red is difficult to match.

You can barely see it in the photo but the label contains the color components that went into creating the final color.

With the paint now in our possession, we could continue with the repairs to the body.

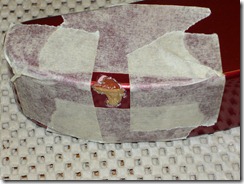

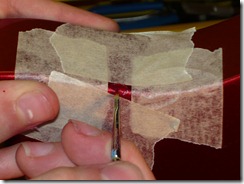

We applied a couple coats of paint. Remember that it’s better use a couple of thin layers than fewer thick one. When the paint was dry, we applied a couple layers of CA to bring the area flush.

When the CA was dry, we carefully sanded the area with some 1200 and 1500 grid sandpaper (I got mine from an auto-parts store. I’ve never seen anything that fine at a hardware store). Unfortunately the sandpaper dulled the shine in the surrounding area so I put my polishing wheel in the hand-drill and was able to restore the shine.

Here are before and after photos of one of the chipped areas.

It’s not perfect. The color turned out to be just a shade too dark but it’s better than what we started with.

No comments:

Post a Comment